Introducing our Container Dunnage Bag Container Loading Air Dunnage Bags, the ultimate solution for cargo protection during transportation. Designed with utmost precision and quality, these dunnage bags are a must-have for any shipping operation.

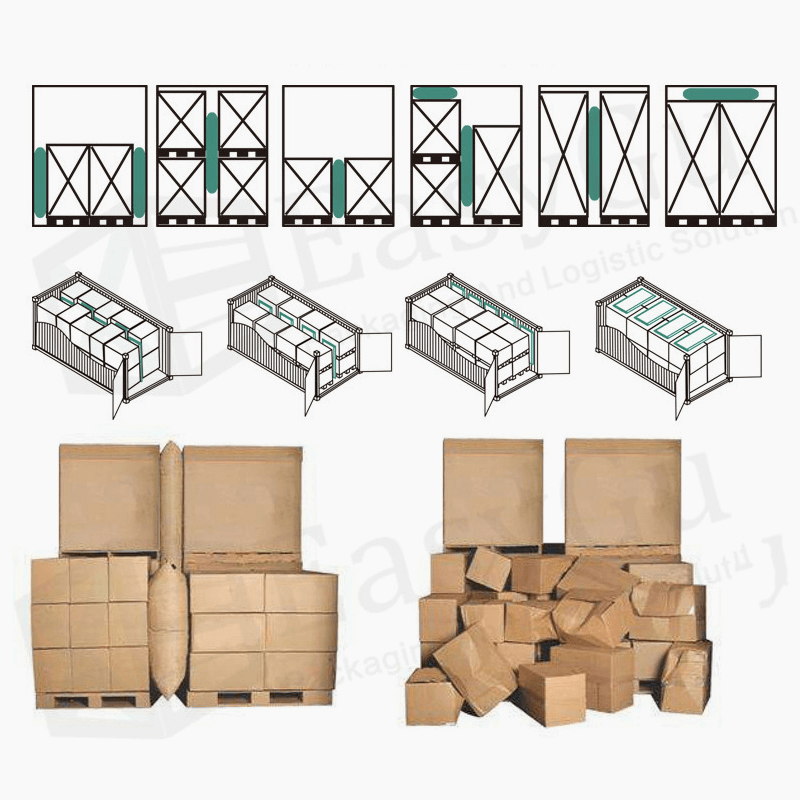

Our Container Dunnage Bag Container Loading Air Dunnage Bags are specifically engineered to secure and stabilize cargo within shipping containers, preventing any potential damage or shifting during transit. With their exceptional strength and durability, these bags provide an extra layer of protection, ensuring that your valuable goods reach their destination intact.

Featuring advanced air-filled technology, our dunnage bags are easily inflated and deflated, making them incredibly convenient to use. The adjustable pressure control allows for a customized fit, ensuring a snug and secure fit for any cargo size or shape. This versatility makes our dunnage bags suitable for a wide range of industries, including automotive, electronics, pharmaceuticals, and more.

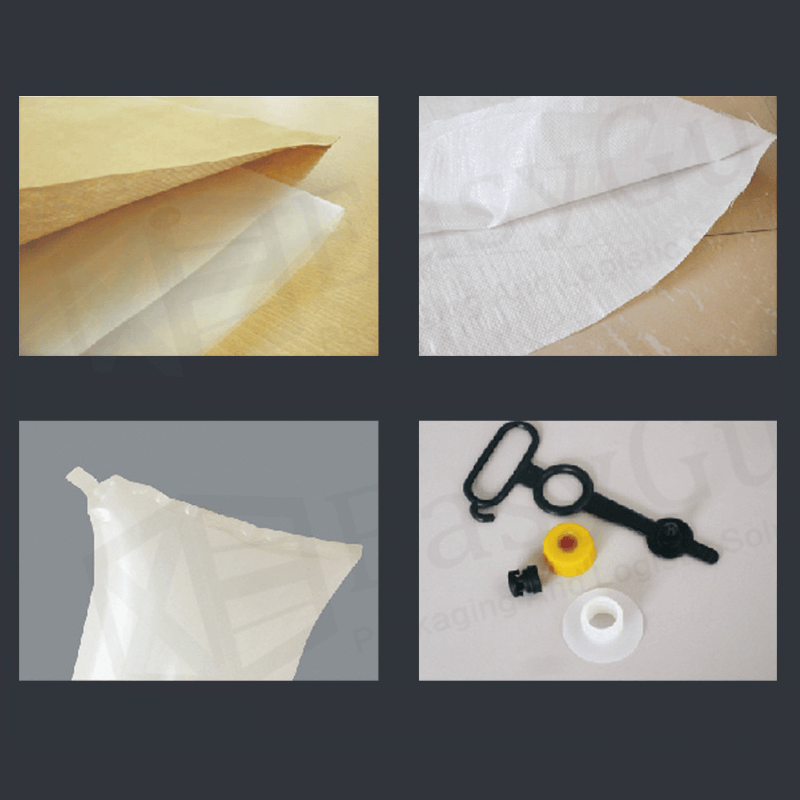

Crafted from high-quality materials, our Container Dunnage Bag Container Loading Air Dunnage Bags are resistant to punctures, tears, and abrasions, guaranteeing long-lasting performance even in the most demanding shipping conditions. The professional-grade construction ensures that these bags can withstand the rigors of transportation, providing reliable protection for your cargo every time.

In addition to their exceptional strength, our dunnage bags are also lightweight and easy to handle. This makes them a practical choice for both manual and automated loading processes, saving you time and effort. With their quick and hassle-free installation, you can maximize efficiency and streamline your shipping operations.

| (W*H) | Use gap | Use height | Use pressure |

| 1200*2400(mm) | 500(mm) | 2300(mm) | 0.2bar |

| 1200*2200(mm) | 500(mm) | 2100(mm) | 0.2bar |

| 1200*2000(mm) | 500(mm) | 1900(mm) | 0.2bar |

| 1200*1800(mm) | 500(mm) | 1700(mm) | 0.2bar |

| 1200*1200(mm) | 500(mm) | 1100(mm) | 0.2bar |

| 1000*2400(mm) | 450(mm) | 2300(mm) | 0.2bar |

| 1000*2200(mm) | 450(mm) | 2200(mm) | 0.2bar |

| 1000*2000(mm) | 450(mm) | 1900(mm) | 0.2bar |

| 1000*1800(mm) | 450(mm) | 1700(mm) | 0.2bar |

| 1000*1600(mm) | 450(mm) | 1500(mm) | 0.2bar |

| 1000*1500(mm) | 450(mm) | 1400(mm) | 0.2bar |

| 1000*1200(mm) | 450(mm) | 1100(mm) | 0.2bar |

| 900*1800(mm) | 400(mm) | 1700(mm) | 0.2bar |

| 900*1200(mm) | 400(mm) | 1100(mm) | 0.2bar |

| 800*1600(mm) | 350(mm) | 1500(mm) | 0.2bar |

| 800*1200(mm) | 350(mm) | 1100(mm) | 0.2bar |

| 800*1000(mm) | 350(mm) | 900(mm) | 0.2bar |

| 500*1500(mm) | 250(mm) | 1400(mm) | 0.2bar |

| 500*1000(mm) | 250(mm) | 900(mm) | 0.2bar |

Gap below 200mm, use inflatable bags with a width of over 500mm

Gap below 300mm, use inflatable bags with a width of over 800mm

Gap below 400mm, use inflatable bags with a width of over 1000mm

Gap below 500mm, use inflatable bags with a width of 1200mm

▍The Functions And Characteristics Of The Product

For trucks / containers / trains. Gap filling between goods.

Other precautions:

1. The length of an inflatable bag is generally the minimum height of the gap to be filled minus 10CM, and the maximum length minus 40CM is appropriate.

2. When using an inflatable bag, first put it into the gap before inflating it. Inflation should not be too full, and it is sufficient to see that the inflatable bag has already squeezed the goods tightly. Because we are operating

At most times, it is at room temperature. During sea transportation, the temperature inside the container may reach up to 70 ℃, and overcharging may lead to adverse consequences.

3. The bottom of the inflatable bag should not touch the floor to avoid air leakage caused by friction and damage between the inflatable bag and the container floor during container transportation.

4. Avoid direct contact of inflatable bags with sharp corners, protrusions, or sharp edges. Corrugated cardboard can be used to protect areas with burrs.

5. If the gap is too large and the existing inflatable bag does not meet the filling conditions, the gap can be dispersed on both sides to avoid the situation where the contact area between the inflatable bag and the goods is too small, causing explosion or damage due to excessive inflation. Observing the tray beginning to shift during the inflation process indicates that the inflation has reached the requirements and should not be further inflated. Or if it feels more difficult to insert the palm between the inflatable bag and the cargo, it also indicates that the inflation is sufficient. But the most important thing is to choose the appropriate size of the inflatable bag.

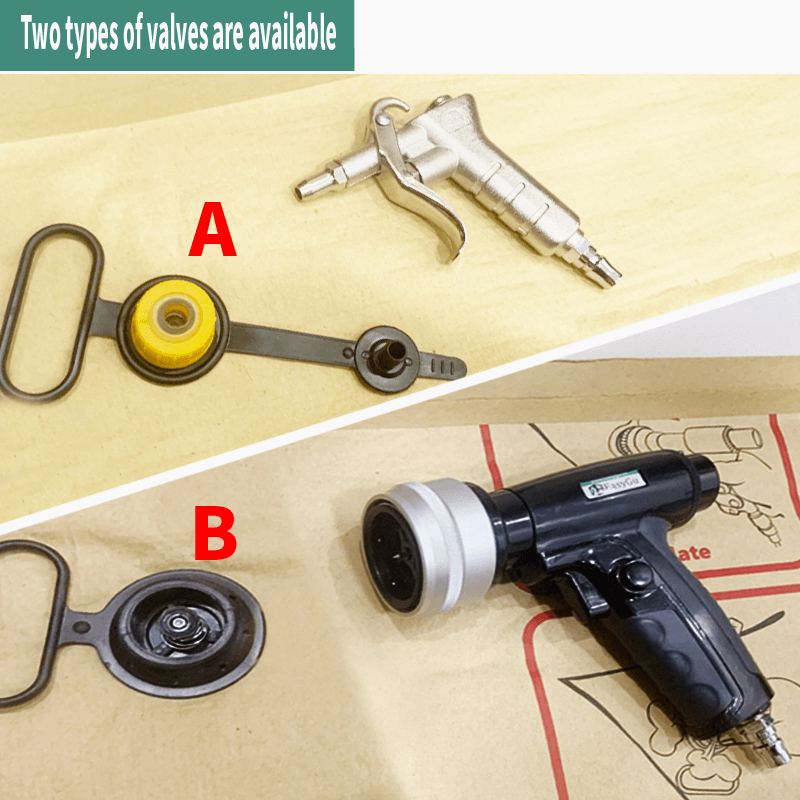

6. After inflation, be sure to confirm again whether the cover of the air nozzle is tightened. Often, the main reason for air leakage is that the cover is not tightened. At the same time, the black handle should be pulled

Insert the stopper into the air nozzle for dual protection.

7. Use the specialized metal inflation gun provided by our company. When inflating, do not unscrew the cover of the air nozzle and inflate directly into the bag to avoid air leakage caused by high-pressure airflow damaging the inner bag.

▍Optional Inflation Tools For Matching

▍Production Process

▍Package & Shipping