Introducing our Inflation Dunnage Bag for Cargo Protection - the ultimate solution for safeguarding your valuable cargo during transportation. Designed with utmost precision and expertise, this product is specifically engineered to provide unparalleled protection and security.

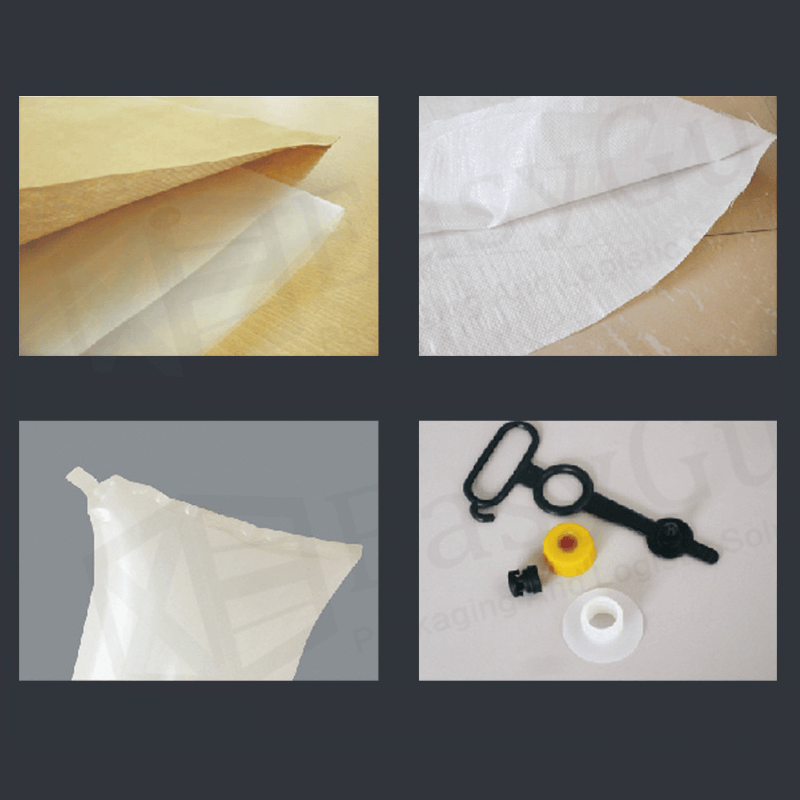

Our Inflation Dunnage Bag boasts a range of exceptional features that make it the ideal choice for cargo protection. Firstly, its robust construction ensures durability and longevity, guaranteeing that your cargo remains intact throughout the entire journey. Crafted from high-quality materials, this bag is resistant to tears, punctures, and abrasions, offering reliable defense against any potential damage.

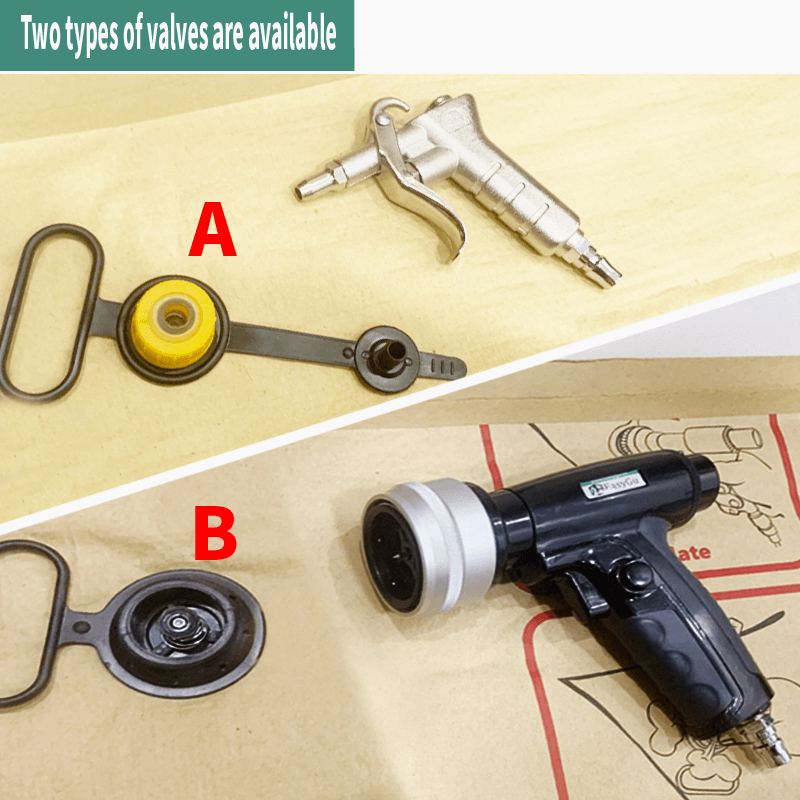

With its innovative inflation mechanism, this dunnage bag allows for quick and effortless deployment. Simply inflate the bag using the provided air pump, and it will instantly create a sturdy cushioning barrier around your cargo. This inflation process ensures a snug fit, preventing any shifting or movement during transit, thus minimizing the risk of impact and collision damage.

Furthermore, our Inflation Dunnage Bag is designed to adapt to various cargo sizes and shapes. Its adjustable straps and buckles enable easy customization, allowing you to secure your cargo tightly and securely. This versatility ensures that the bag can accommodate a wide range of cargo types, making it an indispensable tool for any shipping or logistics operation.

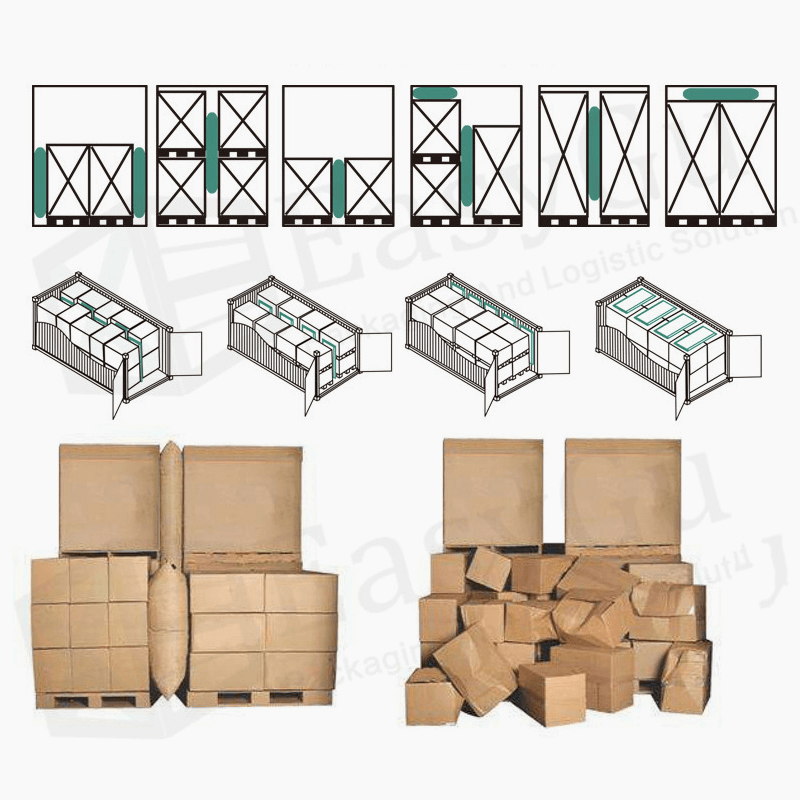

When inflated and installed they reduce the risk of product damage by restricting load movement during transit. can be using for shipping loads by truck, sea container, intermodal, railcar or ocean vessel.

| (W*H) | Use gap | Use height | Use pressure |

| 1200*2400(mm) | 500(mm) | 2300(mm) | 0.2bar |

| 1200*2200(mm) | 500(mm) | 2100(mm) | 0.2bar |

| 1200*2000(mm) | 500(mm) | 1900(mm) | 0.2bar |

| 1200*1800(mm) | 500(mm) | 1700(mm) | 0.2bar |

| 1200*1200(mm) | 500(mm) | 1100(mm) | 0.2bar |

| 1000*2400(mm) | 450(mm) | 2300(mm) | 0.2bar |

| 1000*2200(mm) | 450(mm) | 2200(mm) | 0.2bar |

| 1000*2000(mm) | 450(mm) | 1900(mm) | 0.2bar |

| 1000*1800(mm) | 450(mm) | 1700(mm) | 0.2bar |

| 1000*1600(mm) | 450(mm) | 1500(mm) | 0.2bar |

| 1000*1500(mm) | 450(mm) | 1400(mm) | 0.2bar |

| 1000*1200(mm) | 450(mm) | 1100(mm) | 0.2bar |

| 900*1800(mm) | 400(mm) | 1700(mm) | 0.2bar |

| 900*1200(mm) | 400(mm) | 1100(mm) | 0.2bar |

| 800*1600(mm) | 350(mm) | 1500(mm) | 0.2bar |

| 800*1200(mm) | 350(mm) | 1100(mm) | 0.2bar |

| 800*1000(mm) | 350(mm) | 900(mm) | 0.2bar |

| 500*1500(mm) | 250(mm) | 1400(mm) | 0.2bar |

| 500*1000(mm) | 250(mm) | 900(mm) | 0.2bar |

When inflated and installed they reduce the risk of product damage by restricting load movement during transit. Additionally, dunnage air bags reposition the load and create a bulkhead, further preventing load shifts.

Why do we need to use container filled airbags?

Containers may experience bumps, vibrations, and collisions during transportation, all of which can cause damage to the goods. Filling air bags can fill the gaps inside the container, reduce the movement and collision of goods during transportation, and thus protect the integrity of the goods.

How does the filling airbag work?

Inflatable bags are usually made of soft plastic materials that can be inflated to fill the gaps inside the container. When the airbag is filled with gas, it forms a sturdy support structure to prevent the cargo from moving inside the container.

▍The Functions And Characteristics Of The Product

For trucks / containers / trains. Gap filling between goods.

▍Optional Inflation Tools For Matching

▍Production Process

▍Package & Shipping