In the world of shipping and logistics, ensuring that cargo arrives at its destination in the same condition it was dispatched is paramount. Amidst the numerous technologies and practices developed to protect freight, dunnage air bags stand out for their simplicity and effectiveness. Originally conceived in the 1970s, these inflatable bags have evolved to become a crucial element in cargo stabilization, preventing movement and potential damage during transit. This article aims to delve into what dunnage air bags are, their uses, and why they are indispensable in modern transportation.

So, what exactly is a dunnage air bag?

Dunnage air bags are inflatable devices used to secure and stabilize cargo within transport containers, trucks, railcars, and ships. By filling the voids between cargo, they prevent goods from shifting during transit. These bags are designed to withstand the forces of movement, providing an economical and efficient solution to minimize damage. In this article, we will explore their construction, benefits, types, and application techniques, offering a comprehensive understanding of why dunnage air bags are integral to safe shipping.

The Construction and Types of Dunnage Air Bags

Dunnage air bags come in various shapes, sizes, and materials, tailored to different transportation needs. Understanding their construction and types is essential to grasp their utility fully.

Materials and Layers

Dunnage air bags are typically made from a combination of durable materials. The most common types include:

Kraft Paper: These bags are constructed from multiple layers of kraft paper and are ideal for light to medium-weight cargo. They are biodegradable and provide a cost-effective option for domestic and short-haul transportation.

Polywoven Fabric: Comprising woven polypropylene or polyethylene, these bags are robust and versatile, suitable for a wide range of cargo weights and conditions. They are often reinforced with inner plastic liners to ensure air retention and durability.

Vinyl: For heavy-duty applications, vinyl bags offer superior strength and moisture resistance, making them perfect for international shipping and extreme environments.

Each dunnage air bag consists of an inflatable bladder encased in these materials, with a valve for inflation and deflation. The number of layers and the specific material composition depend on the intended use and the level of protection required.

Sizes and Capacities

Dunnage air bags vary significantly in size, from small bags suitable for compact cargo spaces to large ones that can fill substantial gaps between pallets or crates. Their load-bearing capacities are also diverse, ranging from a few hundred pounds to several tons. Selecting the appropriate size and capacity is crucial to ensure effective cargo stabilization without overloading the bags, which could lead to rupture.

Types of Dunnage Air Bags

Single-Use Bags: Designed for one-time use, these are cost-effective and ideal for shipments where bag retrieval is impractical. They are commonly used in domestic shipping.

Reusable Bags: Constructed from more durable materials, these bags can be inflated and deflated multiple times, offering an economical option for regular shippers.

Heavy-Duty Bags: Specifically engineered for heavy and oversized cargo, these bags provide maximum strength and stability, often used in international and intermodal transport.

Benefits of Using Dunnage Air Bags

The adoption of dunnage air bags in the shipping industry brings numerous advantages, making them a preferred choice for cargo protection.

Cost-Effectiveness

Dunnage air bags are relatively inexpensive compared to other cargo stabilization methods such as wooden bracing or metal straps. Their lightweight nature also reduces overall shipping costs by minimizing additional weight and the need for complex installation processes. For businesses looking to balance cost and protection, these bags provide an optimal solution.

Efficiency and Ease of Use

These bags are straightforward to deploy and require minimal labor. Once placed between cargo, they can be quickly inflated using compressed air, filling gaps and conforming to the shape of the cargo. This adaptability reduces the need for precise packing and speeds up loading and unloading processes. For busy shipping operations, the time saved with dunnage air bags is invaluable.

Environmental Benefits

With an increasing emphasis on sustainable practices, dunnage air bags offer an eco-friendly alternative to traditional packing materials. Many bags, especially those made from kraft paper or polywoven fabric, are recyclable and reusable. Their use reduces the demand for single-use plastics and other non-biodegradable materials, contributing to greener shipping practices.

Versatility

Dunnage air bags are suitable for a wide range of cargo types and transportation modes. Whether securing delicate electronics in a truck, stabilizing heavy machinery in a railcar, or protecting mixed loads in a shipping container, these bags can be tailored to specific needs. Their versatility ensures they can meet the diverse requirements of modern logistics.

Damage Prevention

The primary function of dunnage air bags is to prevent cargo movement and the resulting damage. By filling voids and absorbing shocks, they keep goods secure during transit, reducing the risk of product loss and customer dissatisfaction. This protective quality is especially vital for high-value or fragile items.

Proper Usage and Application Techniques

While dunnage air bags are simple to use, proper application is critical to maximizing their benefits and ensuring cargo safety.

Placement and Inflation

To effectively stabilize cargo, dunnage air bags should be strategically placed in gaps between items. It's important to ensure the bags do not overhang or extend beyond the edges of the cargo, as this could lead to uneven pressure distribution and potential bag failure. Using the correct inflation device, inflate the bags until they snugly fill the space without over-inflating, which could cause rupture under pressure.

Securing Different Types of Cargo

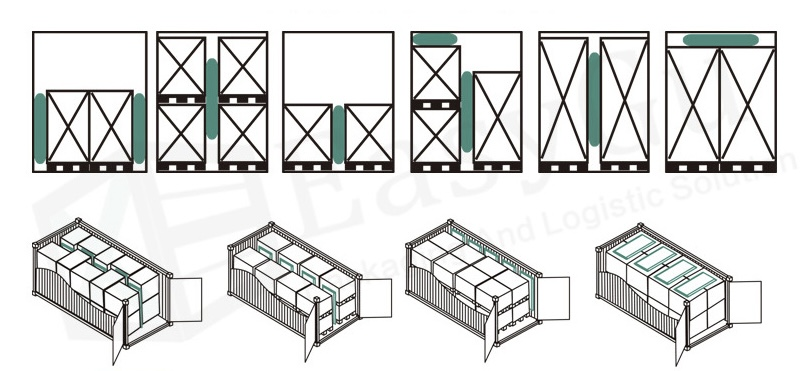

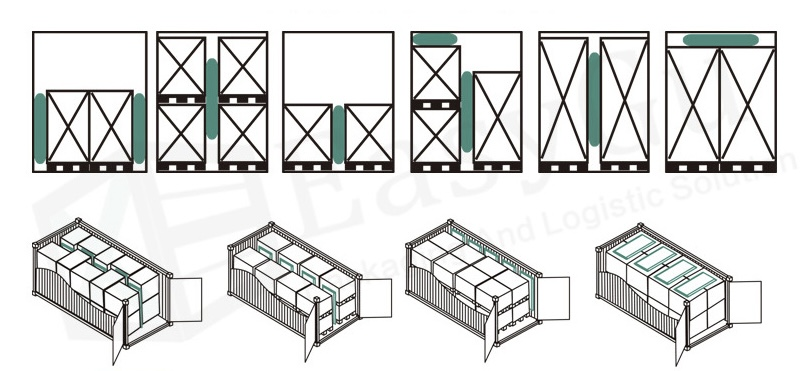

Palletized Loads: For loads on pallets, place the air bags vertically between pallets to prevent lateral movement. Ensure they are supported on all sides to avoid slipping or collapsing.

Loose or Irregular Items: In cases where cargo items are loose or irregularly shaped, use multiple smaller bags to stabilize different sections, ensuring comprehensive protection.

Mixed Loads: When dealing with mixed loads, such as different-sized boxes or crates, position the bags in a way that creates a consistent barrier across the cargo, preventing gaps and maintaining stability.

Maintenance and Inspection

For reusable dunnage air bags, regular inspection and maintenance are crucial. Check for any signs of wear, tears, or leaks before each use. After use, deflate the bags and store them in a clean, dry environment to extend their lifespan. Proper care and handling will ensure they remain effective and safe for repeated use.

Compliance with Regulations

Different modes of transportation may have specific regulations regarding the use of dunnage air bags. For example, rail transport often requires bags to meet certain burst strength standards to ensure safety. Always verify that the bags used comply with relevant regulations and guidelines to avoid potential penalties or cargo rejection.

Common Questions about Dunnage Air Bags

1. Can dunnage air bags be reused?

Yes, many dunnage air bags are designed for multiple uses, especially those made from durable materials like polywoven fabric or vinyl.

2. Are dunnage air bags suitable for international shipping?

Absolutely. Dunnage air bags are widely used in international shipping due to their ability to stabilize heavy and diverse cargo in containers and trucks.

3. How do you choose the right size of a dunnage air bag?

The right size depends on the cargo dimensions and the gaps that need to be filled. It's important to select a bag that fits snugly without being over-inflated to avoid rupture under pressure.

Conclusion

Dunnage air bags represent a versatile, cost-effective, and efficient solution for securing cargo across various transportation modes. From their diverse material options to their ease of use and environmental benefits, these inflatable bags are indispensable in maintaining the integrity of goods during transit. By understanding their construction, benefits, and proper application techniques, shippers can significantly reduce the risk of cargo damage and enhance overall shipping efficiency.