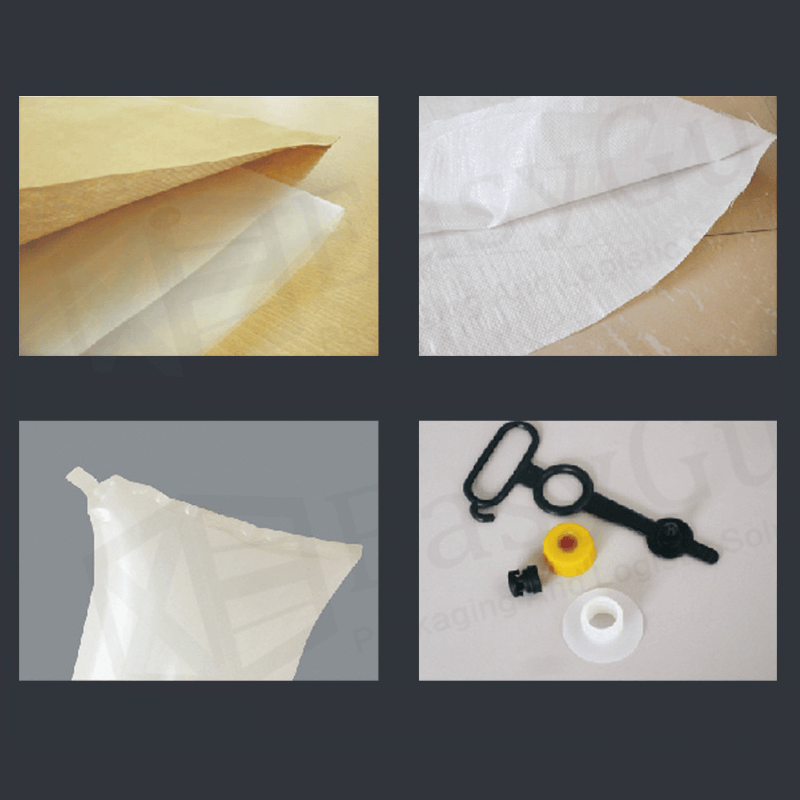

The filling airbag is a protective device used for container filling, usually made of high-strength polyethylene film, with a one-way check valve that can quickly inflate and maintain gas leakage.

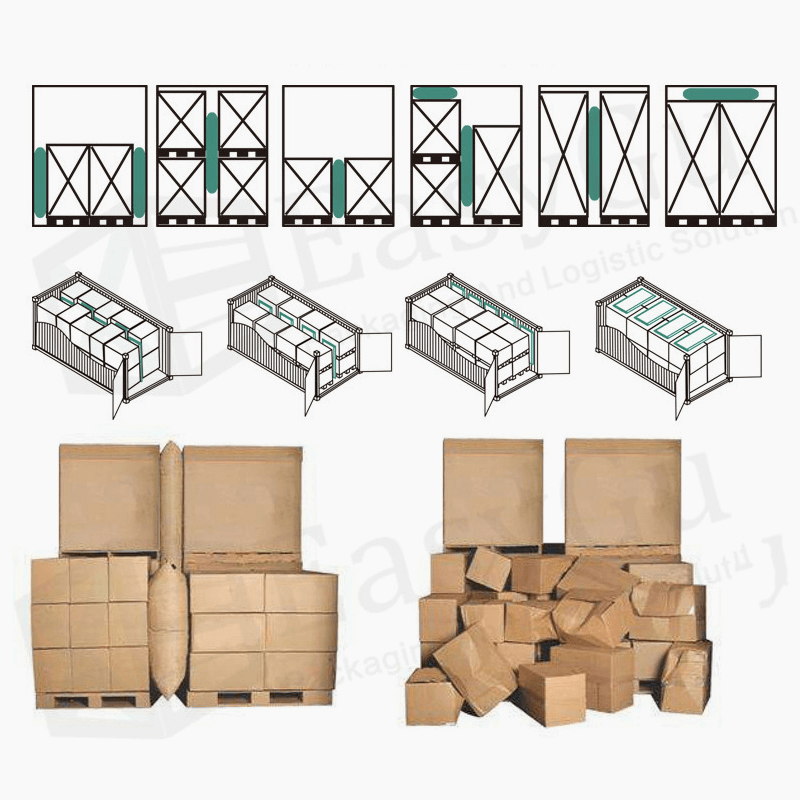

Function: Inflatable bags can effectively prevent the movement of goods during truck, container, or railway transportation, fully fill the gaps between goods, support the weight of goods caused by shaking, absorb vibrations, and protect goods from damage during transportation.

Advantages:

Easy to operate: No need for external equipment, fast inflation, simple and fast operation, can greatly improve packing speed, save labor and labor costs;

Reusable: The filled air bag can be reused, reducing packaging costs;

Environmental protection: Compared with traditional fillers, such as foam plastic, the filled air bag is more environmentally friendly;

Customization: It can be customized according to the specifications of the goods and the gaps generated, making protection more perfect;

Under high pressure: can withstand 4-7 tons of pressure.

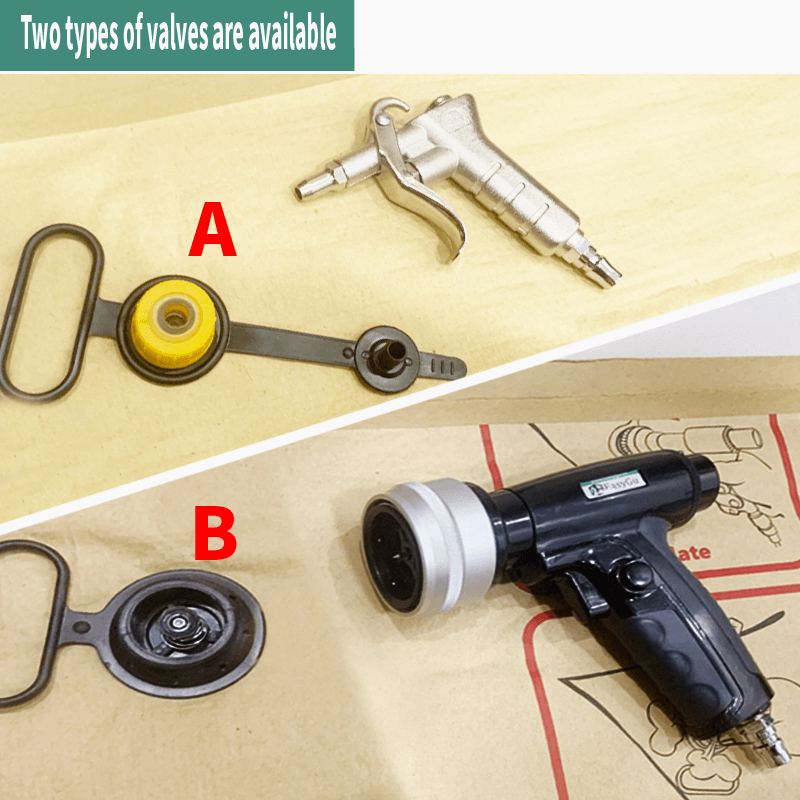

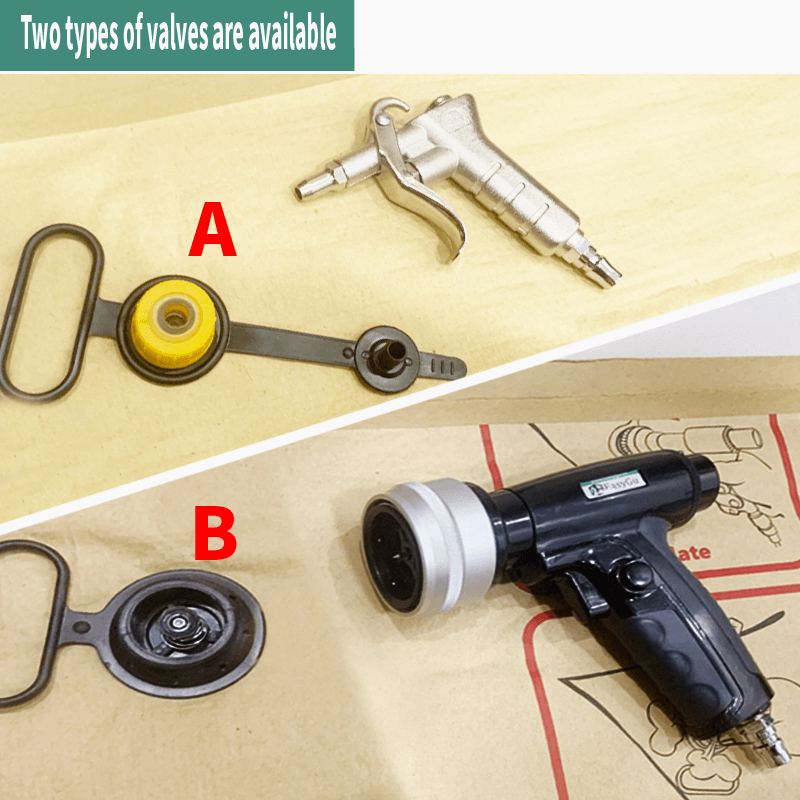

Auxiliary tools: Use air compressors, air guns, steam guns, or dust guns for inflation.

Specifications and Scope of Use: There are various specifications for filling air bags, including 500mm 1000mm, 800mm 1200mm, 1000mm * 1800mm, etc. Suitable specifications can be selected according to actual needs. Inflatable bags are suitable for various transportation methods, such as containers, sea freight, trailers, trains, etc., and are particularly suitable for palletized, whole board, and batch containerized transportation of goods.

| (W*H) | Use gap | Use height | Use pressure |

| 1200*2400(mm) | 500(mm) | 2300(mm) | 0.2bar |

| 1200*2200(mm) | 500(mm) | 2100(mm) | 0.2bar |

| 1200*2000(mm) | 500(mm) | 1900(mm) | 0.2bar |

| 1200*1800(mm) | 500(mm) | 1700(mm) | 0.2bar |

| 1200*1200(mm) | 500(mm) | 1100(mm) | 0.2bar |

| 1000*2400(mm) | 450(mm) | 2300(mm) | 0.2bar |

| 1000*2200(mm) | 450(mm) | 2200(mm) | 0.2bar |

| 1000*2000(mm) | 450(mm) | 1900(mm) | 0.2bar |

| 1000*1800(mm) | 450(mm) | 1700(mm) | 0.2bar |

| 1000*1600(mm) | 450(mm) | 1500(mm) | 0.2bar |

| 1000*1500(mm) | 450(mm) | 1400(mm) | 0.2bar |

| 1000*1200(mm) | 450(mm) | 1100(mm) | 0.2bar |

| 900*1800(mm) | 400(mm) | 1700(mm) | 0.2bar |

| 900*1200(mm) | 400(mm) | 1100(mm) | 0.2bar |

| 800*1600(mm) | 350(mm) | 1500(mm) | 0.2bar |

| 800*1200(mm) | 350(mm) | 1100(mm) | 0.2bar |

| 800*1000(mm) | 350(mm) | 900(mm) | 0.2bar |

| 500*1500(mm) | 250(mm) | 1400(mm) | 0.2bar |

| 500*1000(mm) | 250(mm) | 900(mm) | 0.2bar |

Gap below 200mm, use inflatable bags with a width of over 500mm

Gap below 300mm, use inflatable bags with a width of over 800mm

Gap below 400mm, use inflatable bags with a width of over 1000mm

Gap below 500mm, use inflatable bags with a width of 1200mm

▍The Functions And Characteristics Of The Product

For trucks / containers / trains. Gap filling between goods.

Other precautions:

1. The length of an inflatable bag is generally the minimum height of the gap to be filled minus 10CM, and the maximum length minus 40CM is appropriate.

2. When using an inflatable bag, first put it into the gap before inflating it. Inflation should not be too full, and it is sufficient to see that the inflatable bag has already squeezed the goods tightly. Because we are operating

At most times, it is at room temperature. During sea transportation, the temperature inside the container may reach up to 70 ℃, and overcharging may lead to adverse consequences.

3. The bottom of the inflatable bag should not touch the floor to avoid air leakage caused by friction and damage between the inflatable bag and the container floor during container transportation.

4. Avoid direct contact of inflatable bags with sharp corners, protrusions, or sharp edges. Corrugated cardboard can be used to protect areas with burrs.

5. If the gap is too large and the existing inflatable bag does not meet the filling conditions, the gap can be dispersed on both sides to avoid the situation where the contact area between the inflatable bag and the goods is too small, causing explosion or damage due to excessive inflation. Observing the tray beginning to shift during the inflation process indicates that the inflation has reached the requirements and should not be further inflated. Or if it feels more difficult to insert the palm between the inflatable bag and the cargo, it also indicates that the inflation is sufficient. But the most important thing is to choose the appropriate size of the inflatable bag.

6. After inflation, be sure to confirm again whether the cover of the air nozzle is tightened. Often, the main reason for air leakage is that the cover is not tightened. At the same time, the black handle should be pulled

Insert the stopper into the air nozzle for dual protection.

7. Use the specialized metal inflation gun provided by our company. When inflating, do not unscrew the cover of the air nozzle and inflate directly into the bag to avoid air leakage caused by high-pressure airflow damaging the inner bag.

▍Optional Inflation Tools For Matching

▍Production Process

▍Package & Shipping