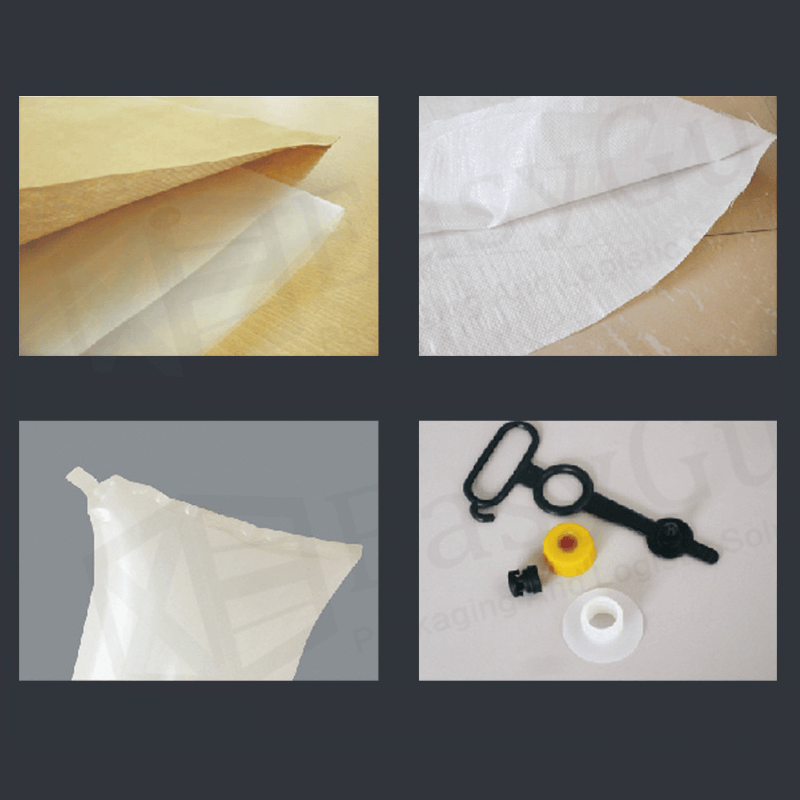

1. Material Composition

2. Multi-Layer Co-Extrusion Technology

Advanced Multi-Layer Co-Extrusion Technology: Tightly combines different material layers to form a sturdy whole.

Surface Kraft Paper Layer: Adds a scratch-resistant kraft paper layer to the surface of the airbag, effectively reducing possible wear and scratches during handling and transportation.

3. Durability

Temperature Range: After rigorous testing, the airbag can maintain stable performance in the temperature range of -30°C to 70°C, without any embrittlement or softening even under extreme environmental conditions.

Chemical Corrosion Resistance: Exhibits good resistance to chemical corrosion, capable of withstanding erosion from common chemical substances.

Product Advantages

Exceptional Material Performance: The combination of polyethylene and nylon provides excellent flexibility, tensile strength, and wear resistance.

Multi-Layer Structure: The use of multi-layer co-extrusion technology and a surface kraft paper layer enhances the overall durability and protective performance of the airbag.

Wide Temperature Adaptability: Maintains stable performance under extreme temperature conditions, making it suitable for various transportation environments.

Chemical Resistance: Resists erosion from common chemical substances, extending the product's lifespan.

Applications

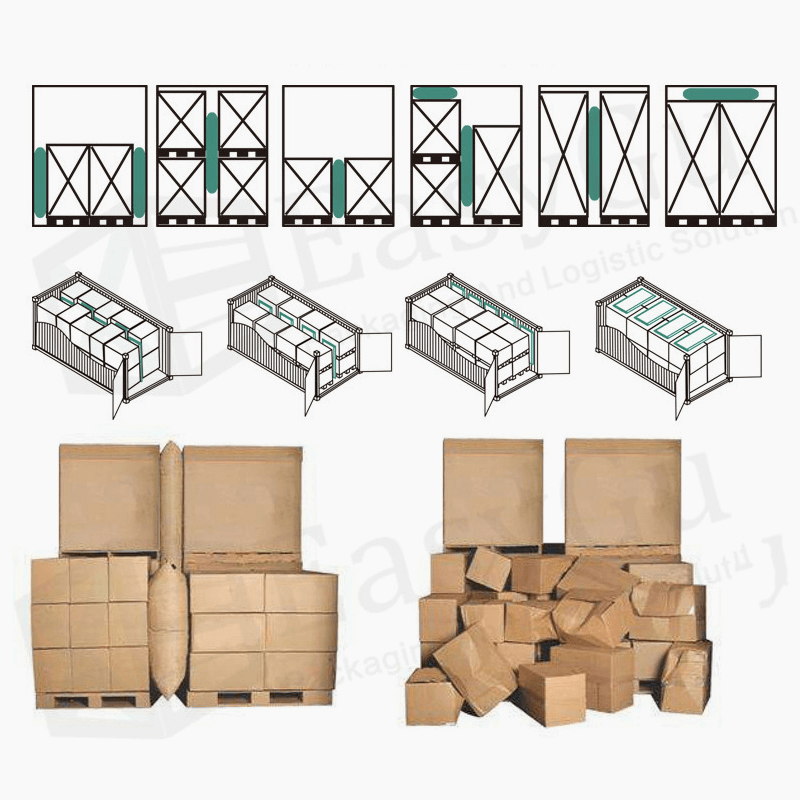

Truck Transportation: Suitable for stabilizing and protecting various types of cargo.

Ocean and Intermodal Freight: Provides additional protection during long-distance transportation, preventing cargo movement and damage.

Rail Transportation: Ensures the safety and stability of cargo under high load and frequent vibration conditions.

The high-performance container filling air bag is a versatile, durable, and efficient transportation protection solution. By using high-quality composite materials and advanced multi-layer co-extrusion technology, it ensures superior protection and stability under various transportation conditions.

If you have any further questions or need additional information,

Please Feel Free to Contact Us!

| (W*H) | Use gap | Use height | Use pressure |

| 1200*2400(mm) | 500(mm) | 2300(mm) | 0.2bar |

| 1200*2200(mm) | 500(mm) | 2100(mm) | 0.2bar |

| 1200*2000(mm) | 500(mm) | 1900(mm) | 0.2bar |

| 1200*1800(mm) | 500(mm) | 1700(mm) | 0.2bar |

| 1200*1200(mm) | 500(mm) | 1100(mm) | 0.2bar |

| 1000*2400(mm) | 450(mm) | 2300(mm) | 0.2bar |

| 1000*2200(mm) | 450(mm) | 2200(mm) | 0.2bar |

| 1000*2000(mm) | 450(mm) | 1900(mm) | 0.2bar |

| 1000*1800(mm) | 450(mm) | 1700(mm) | 0.2bar |

| 1000*1600(mm) | 450(mm) | 1500(mm) | 0.2bar |

| 1000*1500(mm) | 450(mm) | 1400(mm) | 0.2bar |

| 1000*1200(mm) | 450(mm) | 1100(mm) | 0.2bar |

| 900*1800(mm) | 400(mm) | 1700(mm) | 0.2bar |

| 900*1200(mm) | 400(mm) | 1100(mm) | 0.2bar |

| 800*1600(mm) | 350(mm) | 1500(mm) | 0.2bar |

| 800*1200(mm) | 350(mm) | 1100(mm) | 0.2bar |

| 800*1000(mm) | 350(mm) | 900(mm) | 0.2bar |

| 500*1500(mm) | 250(mm) | 1400(mm) | 0.2bar |

| 500*1000(mm) | 250(mm) | 900(mm) | 0.2bar |

Optimized Usage Guidelines for Inflatable Bags

For gaps up to 200mm: Use inflatable bags with a width of over 500mm.

For gaps up to 300mm: Use inflatable bags with a width of over 800mm.

For gaps up to 400mm: Use inflatable bags with a width of over 1000mm.

For gaps up to 500mm: Use inflatable bags with a width of 1200mm.

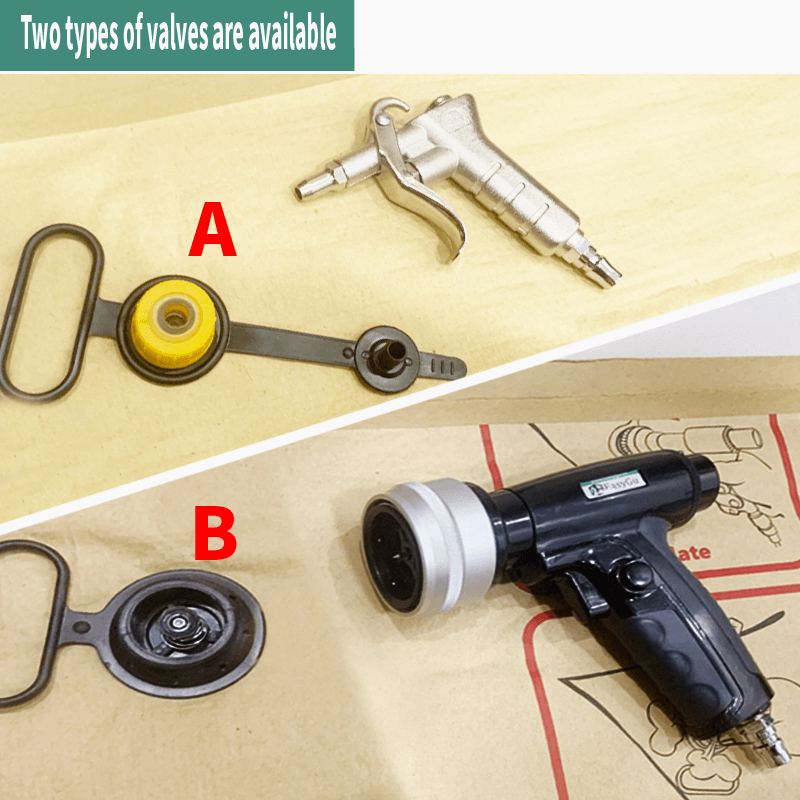

Default shipment with Type A small air valve.

Two different air valve options available.

Please specify your inflation port type to avoid any delays in usage.

Other Precautions:

What size should an inflatable bag be?

The size of the inflatable bag is crucial for effective use. Generally, it should be at least 10 cm shorter than the minimum height of the gap you intend to fill. For the maximum length, it’s best to choose a bag that is 40 cm shorter than the total gap length.

How do you use an inflatable bag properly?

Start by placing the inflatable bag into the gap. Inflate it carefully until it snugly fits against the goods. Why not inflate it too much? Well, since most of our work happens at room temperature, overinflating can be risky. Containers in sea transportation can heat up to 70°C, and excessive inflation might cause issues under such conditions.

How can you protect the inflatable bag from sharp objects?

Keep the bag away from sharp edges, corners, or protrusions. Using corrugated cardboard around these areas can help protect the bag from getting punctured.

What if the gap is too large for the inflatable bag?

If the bag doesn’t fit the gap perfectly, you can adjust by distributing the space evenly on both sides. This helps avoid too much pressure in one area, which can cause the bag to burst or get damaged. How do you know when the bag is properly inflated? When the tray starts to shift slightly or if it becomes difficult to insert your hand between the bag and the cargo, you’ve likely inflated it enough. Always select the right size bag to begin with for the best results.

How do you ensure the inflatable bag doesn't leak after inflation?

After inflating, make sure to tighten the air nozzle cover securely. Often, air leakage is due to a loosely fastened cover. For added security, pull the black handle to insert the stopper into the air nozzle.

What tools should you use to inflate the bag?

Use the specialized metal inflation gun provided by our company. Why not just unscrew the cover and inflate directly? Because doing so can let high-pressure airflow damage the inner bag, leading to leaks.

▍Optional Inflation Tools For Matching

▍Production Process

▍Package & Shipping