Dunnage bags, also known as air bags, are essential tools in the shipping and logistics industry, playing a crucial role in securing cargo during transportation. These inflatable bags are placed between loads to prevent movement and protect against damage caused by shifting during transit. With the increasing globalization of trade and the rise in e-commerce, the safe and efficient transport of goods has become more critical than ever. Dunnage bags provide an effective and economical solution for this, ensuring that products reach their destinations intact. This article will explore the usage of dunnage bags, their benefits, and best practices for their application in various shipping scenarios.

So, how do you use dunnage bags effectively?

The answer is straightforward: by selecting the right type and size of dunnage bag for your cargo, inflating it to the correct pressure, and positioning it strategically within your load. These steps will maximize the stability and protection of your shipment. Let's delve deeper into these aspects to understand how to optimize the use of dunnage bags in your shipping operations.

Selecting the Right Dunnage Bag

Choosing the appropriate dunnage bag is the first critical step in ensuring cargo security. Dunnage bags come in various materials, including paper, polypropylene, and vinyl, each suitable for different shipping needs.

Material Selection: Paper dunnage bags are ideal for light to medium loads and are often used in intermodal and rail transportation. They are environmentally friendly and cost-effective. Polypropylene dunnage bags, known for their strength and durability, are perfect for heavier loads and long-distance shipping. Vinyl dunnage bags are resistant to moisture and chemicals, making them suitable for extreme conditions and sensitive cargo.

Size Consideration: The size of the dunnage bag should correspond to the gaps between the cargo and the type of transportation. Dunnage bags range from small sizes for tight spaces to large bags that fill substantial gaps between pallets or containers. Proper sizing ensures that the bag provides optimal support and prevents load movement.

Load and Pressure Ratings: It's essential to consider the load capacity and the pressure rating of the dunnage bag. These ratings indicate how much weight the bag can support and how much it can be inflated. Overloading or overinflating can compromise the bag’s effectiveness and safety. Always refer to the manufacturer's guidelines for load and pressure specifications.

Environmental Factors: Assess the environmental conditions the cargo will be exposed to during transit. Temperature variations, humidity, and exposure to chemicals can affect the performance of dunnage bags. Select a bag material and type that can withstand the specific conditions of your shipment route.

Proper Inflation Techniques

Inflating dunnage bags correctly is crucial for maintaining cargo stability and maximizing the bag's protective capabilities.

Inflation Equipment: Use the appropriate inflation tools, such as air compressors or manual pumps, designed specifically for dunnage bags. These tools allow precise control over the inflation process, ensuring the bag is inflated to the right pressure.

Air Pressure: Inflate the dunnage bag to the recommended air pressure as specified by the manufacturer. Underinflation can result in inadequate support, while overinflation can cause the bag to burst or create too much pressure on the cargo, potentially causing damage.

Check for Leaks: After inflation, inspect the dunnage bag for any signs of air leakage. Listen for hissing sounds and apply a soapy water solution around the valve and seams to check for bubbles indicating air escape. Immediate detection and repair of leaks prevent potential cargo movement.

Rechecking Pressure: Periodically check the air pressure in the dunnage bags, especially if the cargo is in transit for an extended period. Air pressure can decrease due to temperature changes or prolonged use, so maintaining the correct pressure is vital for ongoing cargo security.

Strategic Placement of Dunnage Bags

The placement of dunnage bags within the cargo load is a key factor in preventing movement and ensuring the stability of the shipment.

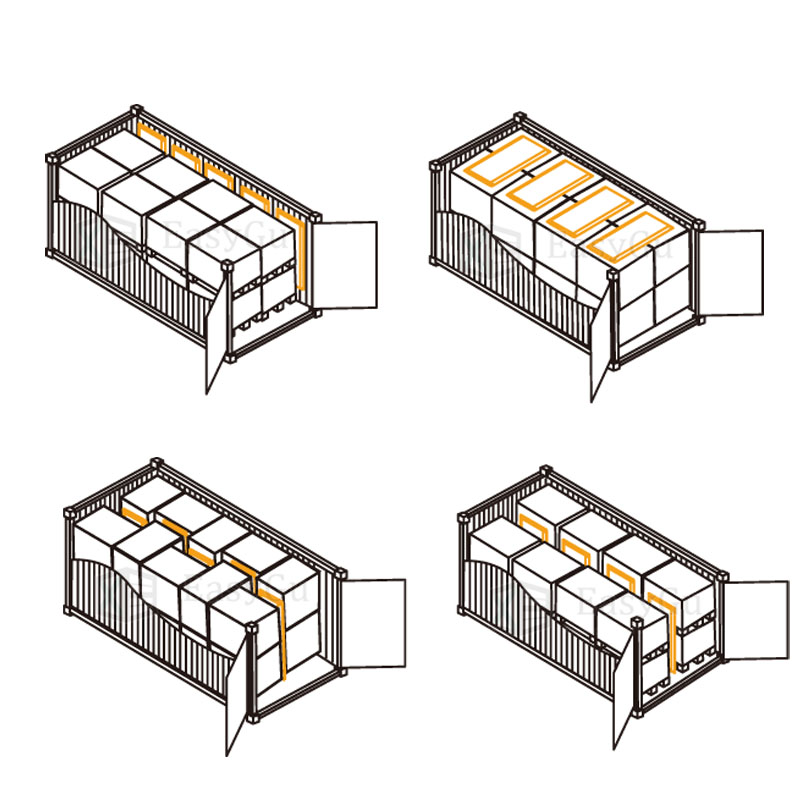

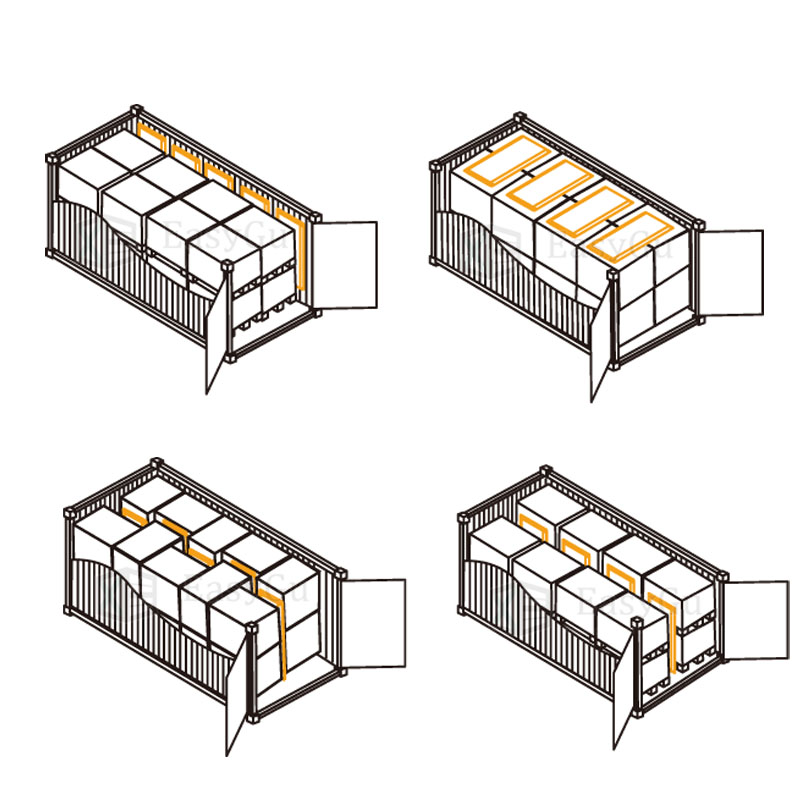

Positioning Between Loads: Place dunnage bags in the gaps between the cargo units. This positioning helps fill voids and provides a cushion that absorbs shocks and vibrations during transit. Ensure that the bags are positioned at the mid-height of the cargo to distribute pressure evenly.

Avoiding Obstructions: Ensure there are no sharp edges, nails, or other objects that could puncture the dunnage bag. The surface against which the bag is placed should be smooth to prevent damage during inflation and transit.

Securing Top Loads: In addition to placing dunnage bags between vertical gaps, consider using them at the top of the load to prevent toppling or shifting. This practice is especially important in containers and trailers with taller loads.

Balanced Distribution: Distribute dunnage bags evenly throughout the load to maintain balance and stability. An uneven distribution can cause the cargo to lean or shift, increasing the risk of damage.

Maintenance and Reusability of Dunnage Bags

Proper maintenance and reusability of dunnage bags contribute to cost savings and environmental sustainability in the long run.

Inspection After Use: After each use, inspect the dunnage bags for any signs of wear and tear. Check for holes, weakened seams, or damaged valves. Identifying and repairing minor issues promptly extends the bag's lifespan.

Proper Storage: Store dunnage bags in a cool, dry place away from direct sunlight and harsh chemicals. Proper storage prevents material degradation and maintains the integrity of the bags for future use.

Cleaning and Sanitizing: Clean dunnage bags before storing them, especially if they have been exposed to dirt, chemicals, or moisture. Use appropriate cleaning agents based on the bag’s material to avoid damage.

Reuse and Recycling: Many dunnage bags, especially those made from durable materials like polypropylene and vinyl, can be reused multiple times. Follow the manufacturer's guidelines for reusability. If a bag is no longer usable, consider recycling options to minimize environmental impact.

Training and Best Practices for Using Dunnage Bags

Ensuring that all personnel involved in the loading and unloading process are adequately trained in the use of dunnage bags is crucial for maximizing their effectiveness.

Comprehensive Training: Provide comprehensive training to all employees on selecting, inflating, and positioning dunnage bags. Include hands-on demonstrations and safety guidelines to ensure understanding and adherence.

Regular Updates: Keep the team updated on the latest best practices and innovations in dunnage bag technology. Regular training sessions and updates help maintain high standards of cargo security.

Safety Protocols: Implement safety protocols to prevent accidents during the handling and installation of dunnage bags. Ensure that employees wear appropriate protective gear and follow safe operating procedures.

Documentation and Record Keeping: Maintain records of dunnage bag usage, including the type, size, and pressure levels used for each shipment. This documentation helps in tracking performance and identifying areas for improvement.

FAQ

Q1: Can dunnage bags be used in all types of transportation?

Yes, dunnage bags can be used in various types of transportation, including road, rail, air, and sea. However, it is important to select the appropriate type and size for each mode of transport.

Q2: How do I know if a dunnage bag is overinflated?

A dunnage bag is overinflated if it feels extremely tight and bulging or if it exerts excessive pressure on the cargo. Always refer to the manufacturer's recommended pressure levels to avoid overinflation.

Q3: Are dunnage bags environmentally friendly?

Many dunnage bags, particularly those made from paper and recyclable plastics, are environmentally friendly. Reusing and recycling dunnage bags contribute to reducing their environmental impact.

By understanding and implementing these guidelines on the selection, inflation, placement, and maintenance of dunnage bags, businesses can enhance the safety and efficiency of their shipping operations. Dunnage bags are not just simple packing tools but are critical components in modern logistics, ensuring that goods are transported securely and arrive in perfect condition.