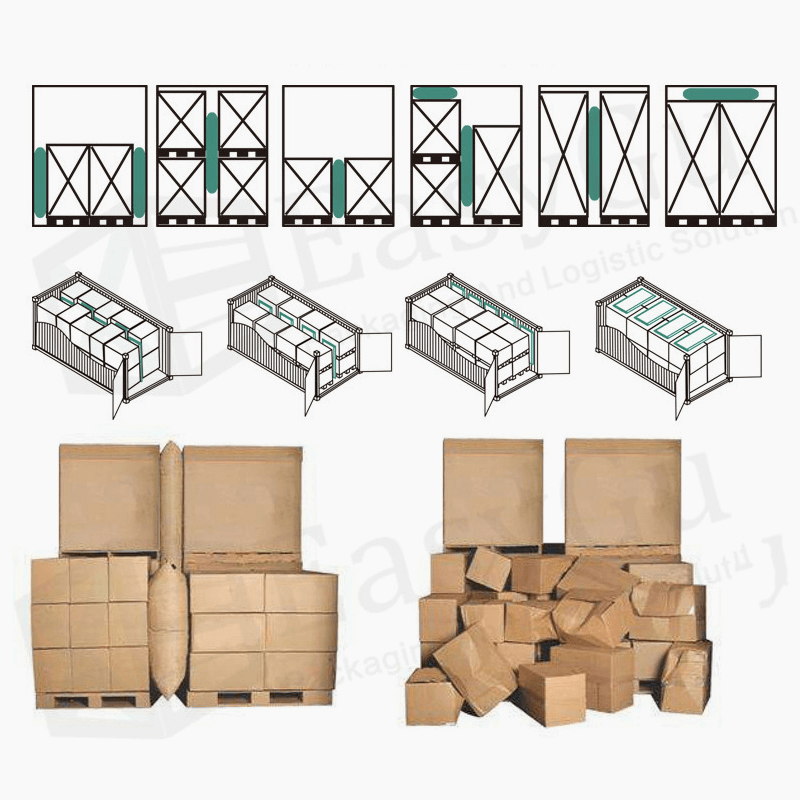

Container filled air bags are an important tool specially designed to ensure the safety of goods during transportation inside containers.

Firstly, it can effectively fill the gaps between the goods and between the goods and the inner walls of the container, preventing collisions and displacement of the goods due to bumps and shaking during transportation, greatly reducing the risk of damage to the goods. Its good cushioning performance can absorb the impact force during transportation, avoiding damage to goods due to violent vibrations.

Secondly, filling the air bag can fix the position of the cargo, keeping it stable, and even under complex transportation conditions, it can maintain a relatively static state, reducing the possibility of cargo tipping and rolling.

Furthermore, its material has a certain strength and toughness, which can withstand certain pressures and provide reliable support and protection for goods.

The use of container filled airbags is easy to operate and can be quickly inflated according to actual needs, adapting to different specifications of goods and containers. Moreover, its cost is relatively low and its cost-effectiveness is high.

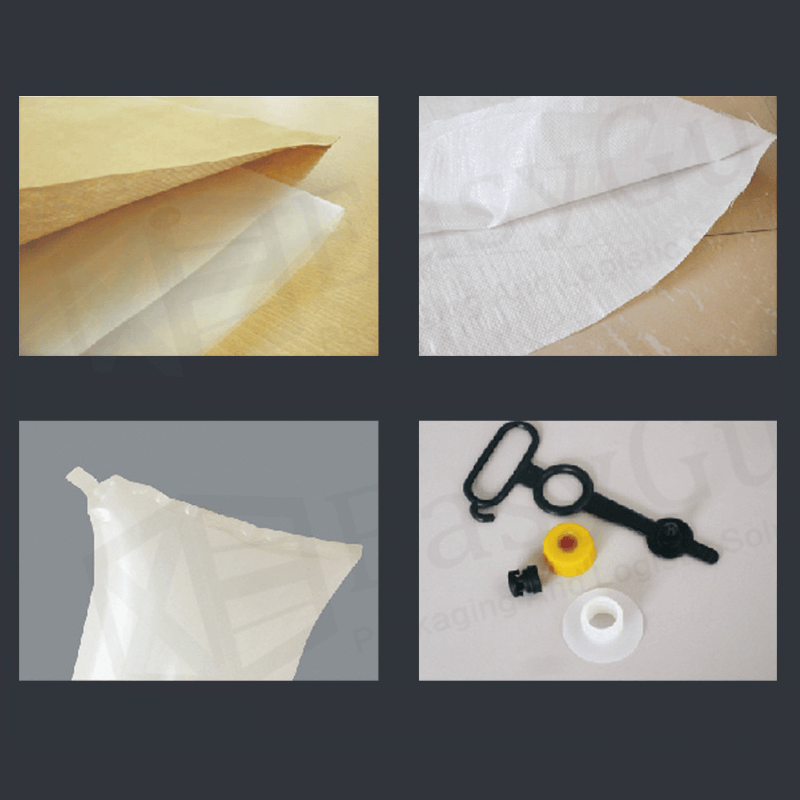

The outer bag of the container filled air bag is usually made of high-strength kraft paper, PP woven bag or PE film, which has characteristics of wear resistance, tear resistance, and waterproofing. The inner bag is generally made of PA (polyamide) or PE (polyethylene) materials, such as PA based 7-layer arch extruded nylon film or PE with nylon material, which have good flexibility and impact resistance.

| (W*H) | Use gap | Use height | Use pressure |

| 1200*2400(mm) | 500(mm) | 2300(mm) | 0.2bar |

| 1200*2200(mm) | 500(mm) | 2100(mm) | 0.2bar |

| 1200*2000(mm) | 500(mm) | 1900(mm) | 0.2bar |

| 1200*1800(mm) | 500(mm) | 1700(mm) | 0.2bar |

| 1200*1200(mm) | 500(mm) | 1100(mm) | 0.2bar |

| 1000*2400(mm) | 450(mm) | 2300(mm) | 0.2bar |

| 1000*2200(mm) | 450(mm) | 2200(mm) | 0.2bar |

| 1000*2000(mm) | 450(mm) | 1900(mm) | 0.2bar |

| 1000*1800(mm) | 450(mm) | 1700(mm) | 0.2bar |

| 1000*1600(mm) | 450(mm) | 1500(mm) | 0.2bar |

| 1000*1500(mm) | 450(mm) | 1400(mm) | 0.2bar |

| 1000*1200(mm) | 450(mm) | 1100(mm) | 0.2bar |

| 900*1800(mm) | 400(mm) | 1700(mm) | 0.2bar |

| 900*1200(mm) | 400(mm) | 1100(mm) | 0.2bar |

| 800*1600(mm) | 350(mm) | 1500(mm) | 0.2bar |

| 800*1200(mm) | 350(mm) | 1100(mm) | 0.2bar |

| 800*1000(mm) | 350(mm) | 900(mm) | 0.2bar |

| 500*1500(mm) | 250(mm) | 1400(mm) | 0.2bar |

| 500*1000(mm) | 250(mm) | 900(mm) | 0.2bar |

Gap below 200mm, use inflatable bags with a width of over 500mm

Gap below 300mm, use inflatable bags with a width of over 800mm

Gap below 400mm, use inflatable bags with a width of over 1000mm

Gap below 500mm, use inflatable bags with a width of 1200mm

The correct size and type of dunnage air bag is determined by a variety of factors such as the weight of the product, the void size and the transportation mode. Please contact us to speak with a Shipment Securement Specialist, who can determine what type and size airbag is right for you.

What are the shortcomings of filling air bags?

The shortcomings of filling airbags include:

-The need for inflatable equipment increases additional equipment and maintenance costs during transportation.

-The inflated airbag will occupy a certain amount of space and may reduce the loading capacity of goods.

-If the airbag is damaged or leaks, it may cause damage to the goods.

How to choose a suitable filling airbag?

When selecting a suitable filling airbag, the following factors need to be considered:

-The type and characteristics of the goods, such as weight, shape, fragility, etc.

-The size and shape of the container.

-Transportation methods and conditions, such as road transportation, sea freight, or air freight.

-Estimated transportation distance and time.

Can inflatable bags be used for stacking goods?

Inflatable bags can be used for stacking goods, but attention should be paid to the stability and weight distribution of the stacking. When stacking goods, it is important to ensure that the filled air bags are evenly attached and provide appropriate support to prevent the goods from tilting or collapsing.

▍The Functions And Characteristics Of The Product

For trucks / containers / trains. Gap filling between goods.

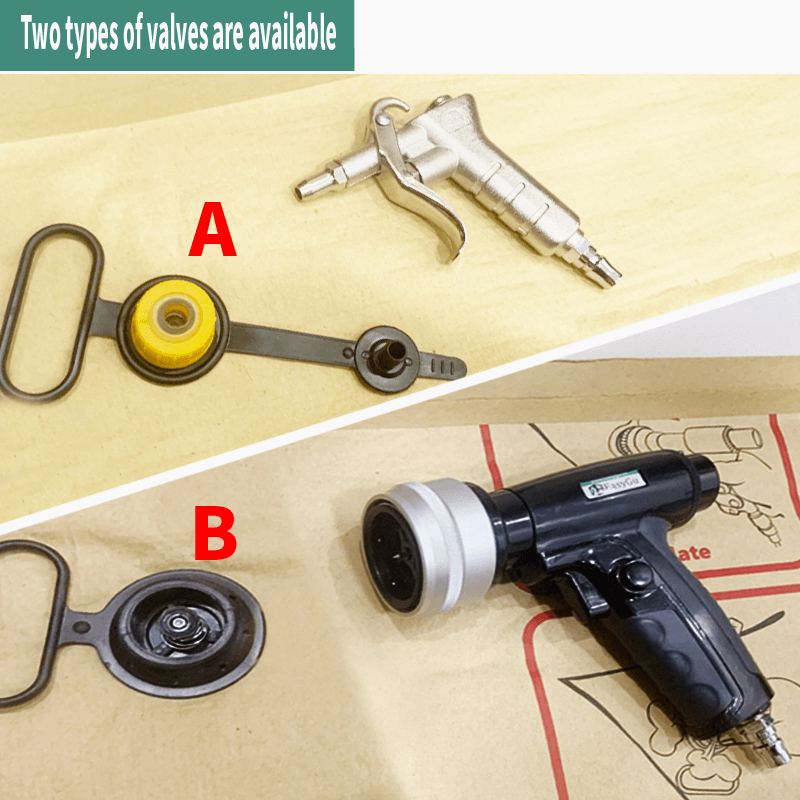

▍Optional Inflation Tools For Matching

▍Production Process

▍Package & Shipping

.